Product Inspiration and Manufacturing Ramp-up

Posting this slightly late project log from last week, as we prepare for some upcoming tasks for FieldKit. We have quite a bit happening in both in the handheld device and in some of our upcoming deployments in the Amazon Rainforest with the Wildlife Conservation Society. More on both those in the coming weeks.

Manufacturing Update

We sent out for the panels for the handheld version to a New Zealand-based PCB supplier that Dan had worked with in the past. This is both for the main MCU and sensor board. They are separated (as Jacob mentioned in an earlier post) so we can mount the sensor board close to the enclosure for more accurate readings. Those sensors measure temperature, humidity, ambient sound, and ambient light.

Jacob has been pulling together the component orders for the pick-and-place machine, which has been an interesting exercise. We have only hand-built PCBs before so our quantities were much lower. Once you start looking into reels and trays of components, the numbers can really add up. Fortunately the common providers like Mouser and Digikey have smaller sub-reels that would be perfect for the runs we plan to do here at the DesignLab. We are still finding the right balance on quantities since we are not in full production yet.

For all the other sensor boards (water quality, weather, etc), we are still ordering the trusty purple boards from out friends at OSH Park. They have been fantastic supporters of FieldKit since the Open Hardware Summit last year.

Product Design Ideation

I have been working a lot on what the look and feel of FieldKit should be as we get into the enclosure design. Jacob and I both come from engineering backgrounds, so some of these industrial/product design stuff is new to us and we were really excited about those opportunities that would come out of the DesignLab residency. I already had a fantastic chat with Majenta and Giovanni about best practices around designing a product like that. The plan is to start on the handheld version (what we frequently call the “Naturalist”) and design some solid 3D prints of potential enclosure designs that we can touch and feel. Using those, I will ask for feedback and we can discuss which one meets the feel that we are seeking for FieldKit in general. As these are to be used out in the field, we want them to have an outdoorsy vibe (much like the stuff that Best Made does so well):

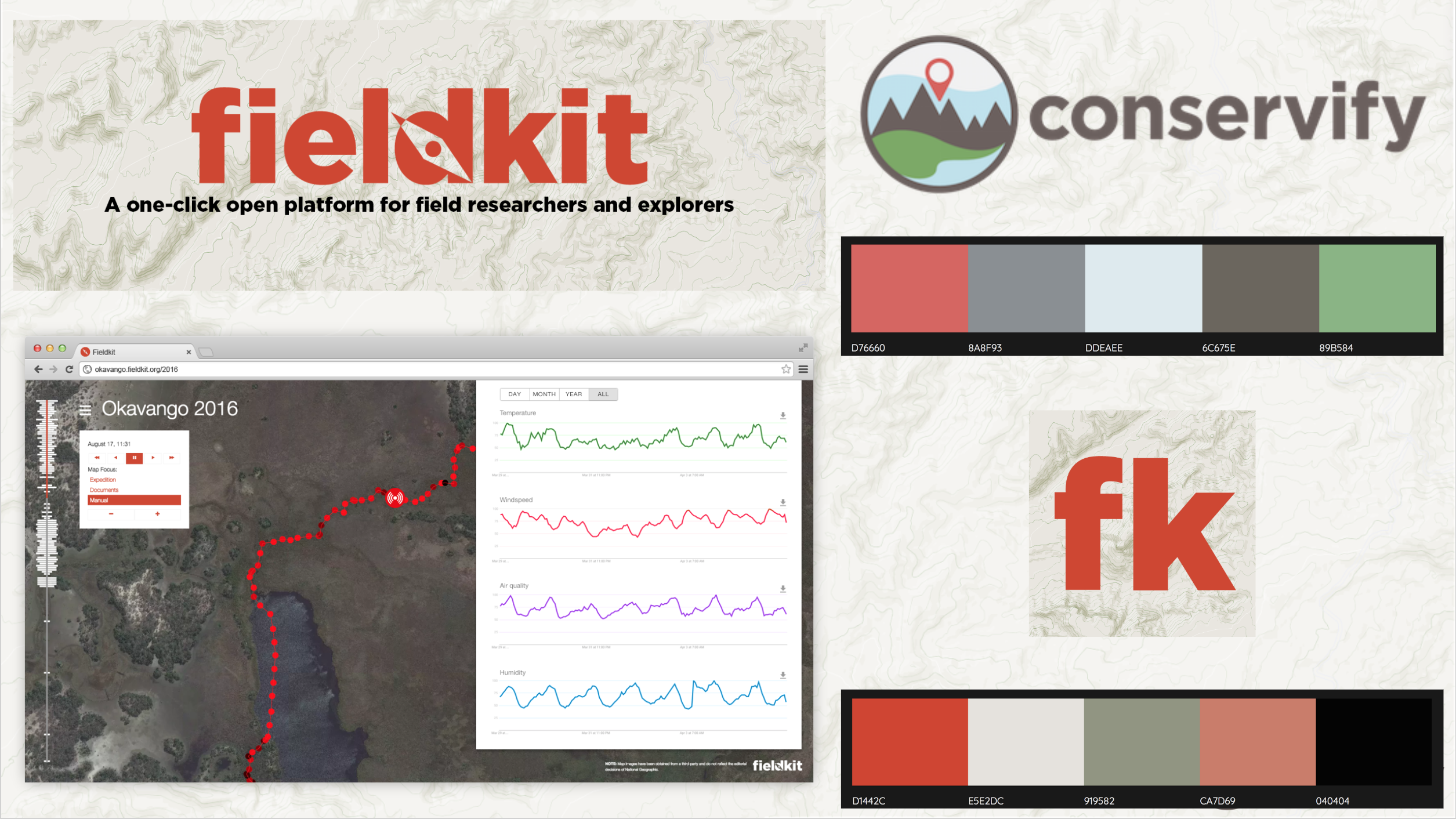

We also want the product to follow the branding that we have built for Conservify and started to develop alongside FieldKit partners Office for Creative Research (which, tragically, is no longer around) and the National Geographic Society. For those who haven’t been following along for long, FieldKit came out of work we had done with OCR since 2014 as part of the Okavango Wilderness Project. That project came out of a collaboration between a few National Geographic Explorers to bring live data from the field during a biodiversity survey expedition in Botswana’s Okavango Delta (more here and here). The branding and color schemes (as currently stands) looks like this:

Finally, there are some functional characteristics that we want for this handheld version. These are:

- It needs two buttons (one to reset the device and another to start the wifi hotspot). We have also been exploring some options on simplifying that to one button and way the devices responds to actuation.

- There needs to be external access to the SD card (to replace/remove) and micro USB plug (for charging and programming)

- The device needs to be designed for outdoor use and appropriately ruggedized

- There might be some potential for interesting mounting options, like a tripod mounting point or loops/slots that allow you to attach the device for in situ measurements.

- The design should influence the user to hold the device in correct orientation for best sensor readings

- Some level (TBD) of waterproof or weather resistant protection should be included

- Some level (TBD) of minimal drop protection should keep it from shattering if dropped in the field

- The material selection or texturing should provide additional grip

So these main thoughts are going into these first few designs, and we will share as we get some ideas flushed out on Fusion360 and off the 3D printers.

During a later project log, I will talk more broadly about some of our users and the community that we have used to develop and test the earlier versions. We have some really interesting deployments in the future. One of those is in the Amazon Rainforest, which we will discuss in our next log.

One more thing…

Oh, and if you never saw our talk at the Hackaday LA meetup earlier this year then check out below. It is a good summary of what we have been up to at Conservify and what FieldKit aspires to solve: