Technical Product Management with a distributed team; Or, Product Plate Spinning.

Sometimes I refer to my job as “Chief Plate Spinner”. There’s something about the comical yet determined spectacle of spinning plates that feels like product management. FieldKit is certainly a technical cross-media product with multiple moving parts. With a lean team of 8 distributed across Los Angeles, Portland OR, New York and Connecticut, we strive to keep our particular plates spinning by continually building on good habits, optimizing workflows, and with a regular dose of face time.

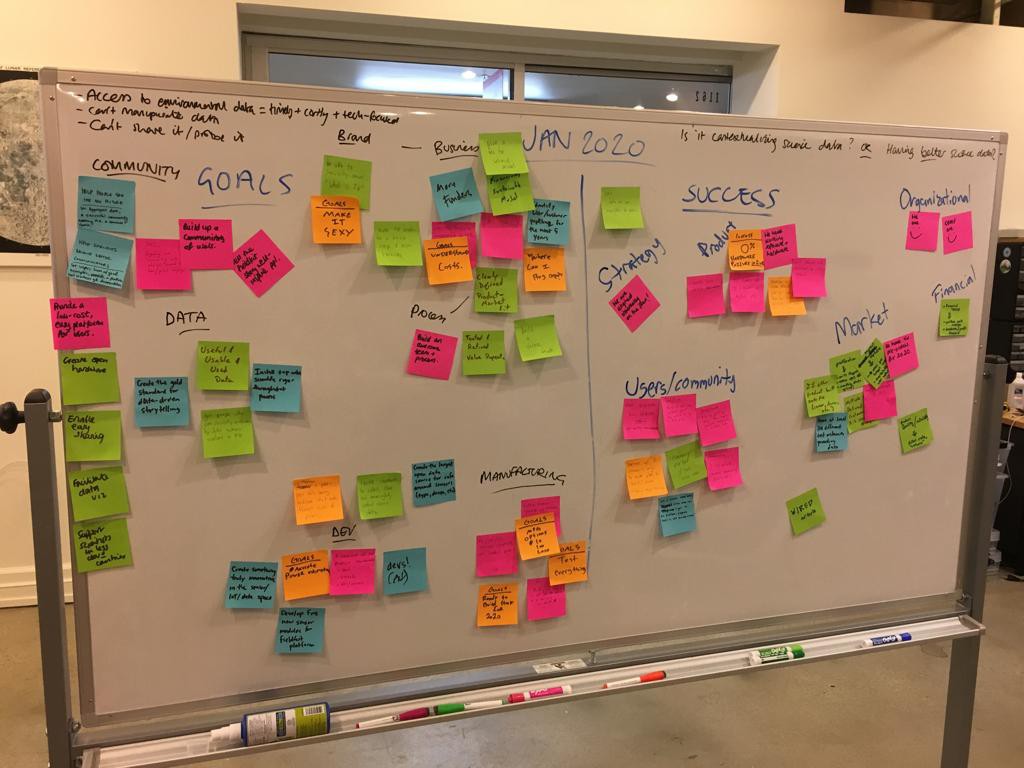

I’m a big fan of starting as you mean to go on. At project kick off, we took the time to set the tone as the whole team gathered in LA to align on FieldKit’s purpose, value and success criteria. Over the next two days, we hashed out our hopes and fears for the product, strategizing about team roles and risk management, and aligning on a clear shared vision.

We tackled the big ticket items first, roughing out an overarching schedule for the year – what the major moments might look like for hardware and software design and production, deployments, and community development. This long term forecast contained key milestones, a prioritized deliverables list, and a critical path for key work streams. This gave us a macro mechanism to monitor progress, anticipate upcoming time and resource crunches, and pivot as necessary. Much of a project like FieldKit is being able to set the ideal pace. Then knowing when to push to meet critical milestones, versus when to re-group and course correct.

With those guideposts in place, we set up a regular rhythm of more detailed systems and processes that would support the work and facilitate the right kinds of conversations. That’s a fancy way of saying we put regular meetings in the calendar, set up an internal wiki with key product documentation and a task tracking system.

The aim of the macro/micro approach was to facilitate productive communication, catch potential issues as early as possible and drive decision-making. We have a ton of ambition, even for a lean mean fighting team! So a concern was potential “analysis paralysis” and a lack of timely decision-making. While one remedy – the “Oh, sh*t!” method – was to visualize just how much we were trying to do and how little time we had left, another was to simply structure regular meetings less around discussions and notes, and more around decisions and actions.

At the heart of the job is greasing the wheels to keep things moving. While sometimes that means pointing nervously to schedules and facilitating decisions, it also means entrusting your team with the expertise and responsibilities they have to deliver on the product vision. Especially with the highly technical aspects of electrical engineering, software programming, and 3D modelling needed to make FieldKit a reality. Other times that means leaning into lean – beyond job titles and technicalities – to hybrid moments that will get the job done. When we filmed the FieldKit prototype film, Lauren our product designer was the talent, I jumped in to help direct, and our product owner Shah was the director of photography!

What remains crucial – especially for a remote team – is coming together for key in-person check-point meetings to not only hold each other accountable, but more importantly to build rapport, celebrate the wins, and galvanize our passion for the work. It’s a privilege to be working on such an important and optimistic product for the world with such a kick-ass team, and sometimes the best way to remember that is to raise a real life glass together!